A Chinese robotics company, UBTech, has received over 500 orders for its industrial humanoid robot, the Walker S1, from major automakers, according to recent reports.

This development is poised to address China’s manufacturing labor shortage as more companies adopt automation technologies to streamline their operations.

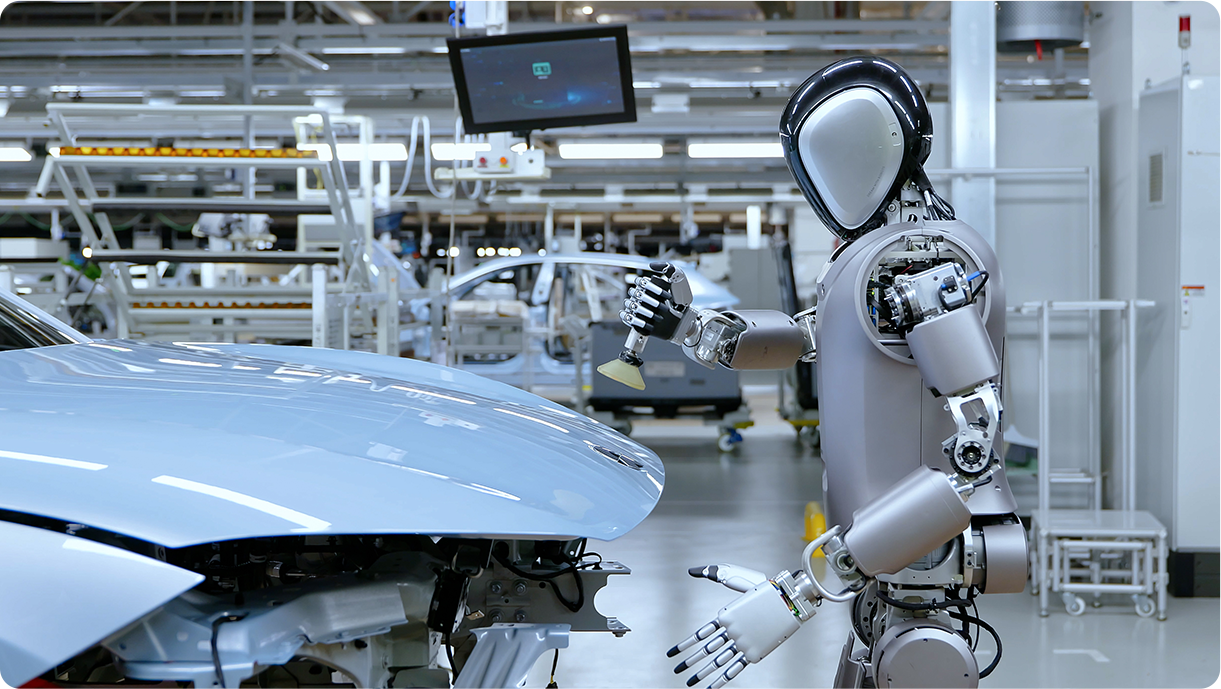

The Walker S1 was officially launched on Monday and is already in use in factories, including those of BYD, the world’s largest electric vehicle manufacturer.

The robot works in conjunction with unmanned logistic vehicles and intelligent manufacturing systems, making it one of the first systems globally to automate large-scale operations to this extent.

Aiming to bridge the labor shortage in manufacturing

China’s manufacturing industry has been grappling with a significant labor shortage. According to a 2017 report by the Ministry of Human Resources and Social Security, key industries like automobile manufacturing are projected to face a shortage of 30 million workers by 2025.

As reported by South China Morning Post (SCMP), UBTech’s chief brand officer, Tan Min, explained in a recent interview that about 70% of the work in automated factories is currently performed by robotic arms, while the remaining 30% is done by humans.

The goal of UBTech is to reduce human labor to only 10% by deploying humanoid robots, with human workers focusing on higher-level tasks such as collaboration and tool management.

“The idea is to replace around 20% of the workload with humanoid robots,” said Tan. This shift toward automation is increasingly necessary as vocational training programs struggle to keep up with the demand for skilled technical workers, and younger university graduates are less inclined to pursue blue-collar jobs.

Walker S1’s capabilities and impact on worker safety

The Walker S1 stands at 5.6 feet (172 cm) tall and weighs 167.6 pounds (76 kg), closely resembling a human in size.

It is designed to handle a variety of tasks within the factory environment, including conducting visual quality inspections, carrying parcels of different sizes, tightening screws with an electric screwdriver, assembling components, and sorting parts.

One of the key benefits of using humanoid robots like the Walker S1 is the reduction in physical strain and injury risks for human workers.

Repetitive tasks such as heavy lifting and exposure to hazardous materials can cause long-term health issues for workers. By taking on these physically demanding and monotonous jobs, the Walker S1 could protect workers from such risks, UBTech stated on its website.

Collaborations with leading industries

UBTech is not new to the automation space, and its growing presence in the industry is evident through its partnerships with leading companies. Backed by Tencent, UBTech made its public debut on the Hong Kong stock exchange in December.

In addition to working with BYD, the company has also secured clients such as state-owned Dongfeng Motor, FAW-Volkswagen, and Geely.

Beyond the automotive industry, UBTech is also collaborating with electronics giant Foxconn and logistics firm SF Express to implement large-scale automated operations. These partnerships illustrate the wide-reaching applications of UBTech’s humanoid robots and their potential to transform not only the manufacturing sector but also logistics and electronics.